- Details

A large international collaboration has used a specialised technique on the infrared microspectroscopy (IRM) beamline at the Australian Synchrotron to determine the structure of proteins in individual silk fibres that has potential use in the design of new biomaterials with desirable properties.

The technique, hyper-spectral infrared imaging, is a powerful analytical tool because it can establish the link between micro-/nano-structures and specific material properties of biomaterials.

The investigation included researchers from Swinburne University, Tokyo Institute of Technology, Deakin University, the Australian Nanofabrication Facility, The Centre for Physical Sciences and Technology in Lithuania, Dr Mark Tobin and Dr Pimm Vongsvivut from the Australian Synchrotron, in a study that was published in Scientific Reports.

The extraordinary properties of silk are linked to the molecular orientation of polypeptides and its amorphous/crystalline composition in the protein structure.

“The goal was to identify the orientation of proteins in different parts of the fibre and to look at how laser treatment can alter the protein structure in the silk fibre,” said Dr Mark Tobin, Principal Scientist ‒ IR beamline at the Australian Synchrotron.

“You would need to know the effect of a laser on silk, for example, in order to 3D print the silk,” said Tobin.

Molecular orientation is responsible for the optical, mechanical and thermal properties of biomaterials. In this study, the researchers were interested in investigating the molecular orientation of specific protein bonds in the silk that play a critical role in its strength.

Infrared imaging at the Australian Synchrotron can access molecular orientation of the protein structure directly from a single silk fibre.

“You can obtain infrared absorption information that is selected based on the orientation of a particular chemical bond,” explained Tobin.

Hyper-spectral imaging

“Because the silk fibres are only 10 microns across and the synchrotron infrared beam is about half the size of that, we developed an optical device using a germanium crystal that allowed the beam to pass through the fibre’s cross section at four times higher resolution.”

This specific device, which was developed by Vongsvivut and Tobin at the Australian Synchrotron, was recently used successfully on carbon fibres and has shown to be efficiently suitable in a broad range of applications.

Silk is a semi-crystalline material that is birefringent, which means as well as absorbing polarised light in one way it actually rotates the polarisation.

The researchers used an infrared filter to progressively rotate the polarisation of the synchrotron beam and collected four infrared (chemical) images ‒ each one with the polarisation 45 degrees apart. This unique four polarisation method was developed by the collaborative researchers in Japan. Using a mathematical formula to transform the polarisation data, they were able to work out the molecular orientation of the protein structure in the silk fibres.

Infrared imaging

In an infrared image, the intensity of the colour indicates the strength of the absorbance.

“In the infrared wavelengths, you see peaks in the spectra that tell you where the light is being strongly absorbed,“ said Tobin.

“A bond vibrates at a certain energy level at a natural frequency. If light comes in at the same frequency, it can absorb some of that infrared light and vibrate to a slightly higher level,” explained Tobin.

The spectra generated in infrared images revealed that the primary vibration of the Amide II bond was all along the direction of the chain and the vibration of the Amide A bond was perpendicular to the fibre.

“With that information, our collaborators were able to work out that the protein molecules oriented in a particular way in the fibre.”

When a pulsed laser was used on one of the bonds, it disrupted the Amide A bond, changing the protein structure.

“Although the bulk information of silk fibres has probably been known, it has not been possible to measure molecular orientation on single fibres before,” said Tobin.

doi:10.1038/s41598-017-07502-3

- Details

Call for nominations

Continuing a tradition set up by the Australian Synchrotron Research Program (ASRP), ANSTO is seeking submissions for the ANSTO, Australian Synchrotron Thesis Medal, named in honour of Dr Stephen Wilkins.

This medal is awarded annually to the PhD student at an Australian or New Zealand University who is judged to have completed the most outstanding thesis of the past two years whose work was undertaken at and acknowledges the Australian Synchrotron, or the Australian National Beamline Facility (ANBF), or whose work acknowledges and was undertaken under the auspices of the International Synchrotron Access Program (ISAP) or the ASRP.

Nominations are invited for the 2017 ANSTO, Australian Synchrotron Stephen Wilkins Medal, which will be awarded to the candidate producing the most outstanding thesis and whose degree was awarded, but not necessarily conferred, in the period 1 July, 2015 – 30 June, 2017. The awardee will receive a monetary prize of $3,000 funded by a bequest from the Wilkins family and by ANSTO to support career development.

Conditions of the Award

· Applicants are able to nominate themselves; however, a letter of support for their application is required from their PhD Supervisor(s).

· To be eligible, applicants must have completed their PhD while enrolled at an Australian or New Zealand University and must have been awarded their PhD within 2 years prior to 30 June of the current year. Applicants may still apply if their PhD has been awarded but not conferred within this time period.

· Nominations are assessed by a Medal Selection Committee appointed by the Director of the Australian Synchrotron, ANSTO.

· The award is made to the PhD student at an Australian or New Zealand University who is judged to have completed the most outstanding thesis of the past two years whose work was undertaken at and acknowledges the Australian Synchrotron, or the ANBF, or whose work acknowledges and was undertaken under the auspices of the ISAP or the ASRP.

· Synchrotron radiation techniques should have made a major contribution to the thesis.

· If the Medal Selection Committee is unable to identify a thesis of sufficient quality amongst the applications submitted, an award will not be offered.

· If the Medal Selection Committee identifies a number of high quality applications in addition to the Awardee, they may offer a “Highly Commended” certificate.

· The Awardee must be available to attend the ANSTO User Meeting to receive their award and present their work in a plenary session.

· ANSTO may publicise successful candidates.

Application Details

There is no application form. Applications can be submitted by either printed or electronic versions, and must include the following:

· Three copies of the thesis along with evidence of the thesis being passed.

· A cover letter providing an overview of the research undertaken during the PhD candidature of the applicant, their academic achievements and future plans for their research career.

· Letters of support from the candidate’s PhD supervisor and Head of Department or School describing the significance of the work and the contribution it has made to the relevant field.

· Copies of the examiners’ reports.

· A list of publications resulting from the thesis.

· A copy of the applicant’s CV.

ANSTO will retain one copy of the successful thesis if submitted in hard copy. All other copies will be returned to the applicants at the end of the selection process.

The Medal will be presented to the chosen candidate at the ANSTO User Meeting 22nd - 24th November 2017. The winning candidate will be invited to attend the User meeting and present a talk on their research.

Any queries should be emailed to [email protected]

Applications should be forwarded to:

Professor Andrew Peele

Director

Australian Synchrotron, ANSTO

800 Blackburn Road

Clayton, Victoria 3168

Application deadline – Close of Business Monday 16th October 2017

- Details

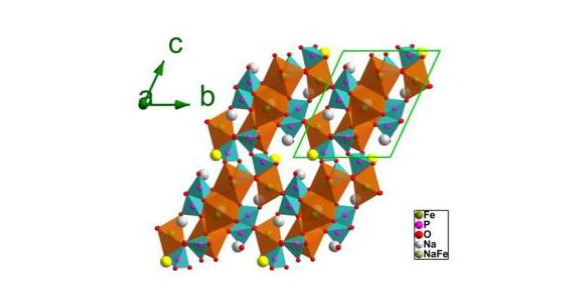

A large collaboration led by researchers from the University of Wollongong has used the Australian Synchrotron to investigate a promising carbon coated cathode material for rechargeable sodium ion batteries that had a very long life.

The research demonstrated that a new compound, an iron-based pyrophosphate-based sodium composite, could compete with other iron-based cathode materials for large scale applications, such as wind and solar storage, because its charge retention capacity was close to 90 per cent after 1100 cycles at 5 C.

Low energy density, sluggish sodium kinetics and poor cycling stability have been the main barriers to the widespread use of sodium ion batteries as less costly alternative to lithium batteries.

The synchrotron was used to investigate the electrochemical mechanism at work in a new cathode material, Na3.32Fe 2.34 (P2O7) as reported in Advanced Materials.

The multiple anions of the new compounds give them high structural and thermal stability with only small volume changes in the unit cell.

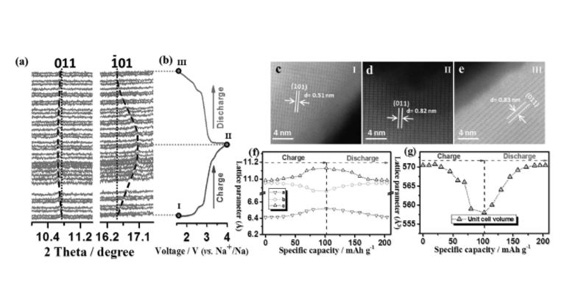

Qinfen Gu, a senior scientist on the powder diffraction beamline, said it was possible to charge and discharge the battery in real time while sending X-rays through the nanoparticles, which revealed what was happening at a structural level in the cathode material during cycling.

The diffraction data indicated a single phase transition during charge and discharge, which helped explain its superior electrical performance.

A reversible electrochemical reaction, suggested by continuous lattice breathing, also took place in the material.

“The movement of the sodium ions can cause the cathode to expand or contract, which can degrade the material and interfere with the movement of electrons,” said Gu.

In this case the researchers noted that only a small change in lattice parameters and unit cell offered strong support for the stability of the structure during cycling.

The application of a carbon coating on the cathode material improved its thermal and structural stability, enhanced its electrical conductivity and contributed to a high rate capacity.

The investigators also attributed superior electrochemical performance to a dramatic increase in the transfer rate of electrons across different layers of the material and an acceleration of the transfer of sodium ions by the uniform amorphous carbon layer.

Experiments confirmed that without the carbon coating, the material degrades very quickly and after 500 cycles, charge retention capacity drops.

“The electrolyte attacks the cathode material and the carbon coating slows this down,” explained Gu.

The material would be low cost because it is primarily composed of ample elements, sodium and iron, and offers improved safety.

Other collaborating institutions included the University of South China, the University of Queensland and Sichuan University (China).